Plastic Molding

Our Plastics Division offers high quality precision molding of injection molded plastic components. We are capable of molding parts with extremely close tolerance and dimensions. We have expertise in processing both engineering and commodity grade plastics.

Materials used include ABS, Acetyl, Bakelite, PBT, PET, Polyethylene, and Polypropylene to name a few. Our Plastic Division can also provide critical post molding services including ultrasonic welding, machining provide sub-component or full product assembly as well as printing, specialized packaging and shipping for local or overseas destinations.

Faraz Industries manufacture, process and assemble OEM parts for world class automotive and engineering market. We are a top tier supplier to large Pakistani automotive OEM marketplaces. Our capabilities range from 150 Ton to 500 Ton machines with up to 28 oz shot capacity.

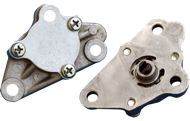

Die Casting

Our die casting division offers aluminum & zinc die casting, machining and finishing supplying complete components to all segments of industry. Serving various customers and producing over 500 different parts per year. Annual volume of 3 to 4 million.

Our Die Casting department delivers high production standards, prompt, reliable service and hands-on customer care. Our die casting department utilizes the latest technology in the market. In conjunction with our machining divisions, we are able to assist in any project, from conceptual design through to the finished component. Our designers are able to advise the most efficient ways to produce high pressure die-castings, and reduce costs to the customer.

Our die cast machine sizes range from 25 Ton – 400 Ton with up to 11 lbs shot size.

CNC & Conventional Machining

Our CNC division utilizes the latest in CNC technology, at Faraz industries we specialize in the supply of componentry to the automotive and engineering industries.

Our CNC division is capable of producing production parts of various materials in high volume, low volume, and prototype quantities to specification. We offer close tolerance machining of steel, cast iron and aluminum, and most ferrous or non-ferrous metal. Our machining services include milling, turning, boring, drilling, lapping, reaming, sanding, and tapping. We also provide finishing operations such as assembly, buffing, chromating, deburring, painting, electroplating, polishing, powder coating, pressure testing, and shot blasting.

We can customize our equipment to match any finish. Our Precision CNC Machining department also produces tooling and fixture components to support our in-house tool room and our customer needs.

Sheet Metal Press Work

Our sheet metal division is equipped to manufacture production components for the automotive and engineering industry. We cater to the specific manufacturing needs of our customers.

Our services include miniature metal stamping, progressive stamping, secondary stamping, custom metal stamping, thin metal stamping, small stamping, press sheet stamping, and fine blanked stamping.

Our presses from 5 to 150 ton capacities provide manufacturing capabilities in materials ranging from 0.005" thickness to 0.125" thickness.

Electroplating

Our electroplating division is dedicated to providing superior quality plating on a wide selection of metal substrates including steel, brass, zinc die-cast, and stainless steel.

We provide decorative copper, nickel, duplex nickel and chromium finishes for most metals. We can customize our equipment to match any finish. Our plating lines are flexible, which allows us to work with small and high volume production needs. Faraz Industries is equipped with wide tanks for steel, brass or zinc die castings that allow us to plate large individual parts or many smaller pieces at one time to be cost effective.

Our In House Lab assures optimum quality by systematically monitoring all chemicals in the cleaning and plating lines. We utilize ampere hour meter, practice volumetric, and hull cell analysis to test and maintain our solution on a regular basis to consistently produce superior products.

Mold & Die Shop

Our mold making division has the talent and technology to design, manufacture and repair both plastic injection molds and die cast dies. We utilize CNC machines, wire EDM and latest techniques to deliver high quality molds. Our specially trained staff with advanced CAD/CAM system and Pro-Engineering 3D design capabilities are extremely helpful in mold designing.

Our design facility is equipped with latest 3D non contact digitizer with laser accuracy by Minolta Vivid 900, it has the capability to scan over 300,000 points in less than one second with range precision to 0.02mm. This reverse engineering has minimized engineering, design time and cost for our end results. For quick communication, we can receive data files via the Internet in, DXF IGES and Pro-Engineer native file formats. For quality assurance every mold that is built or repaired is thoroughly tested on our in-house injection mold presses.